Filtration technology

Terra® suction filters and strainer dryers

The process filter that combines several process steps

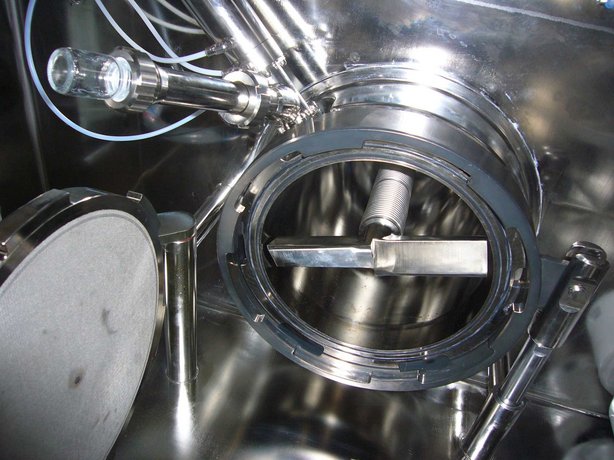

Terra® suction filters are pressure filters that can be sterilised. They work stepwise and allow the combination of different successive process steps in a closed system in a very confined space.

Application:

Terra® suction filters are suitable for processing easily filterable suspensions with a high solids content. Possible process steps: extraction, washing out, blowing out, steaming, vacuum and heating gas drying, dissolving and sublimation, as well as discharge of the solids.

Advantages:

- High quality and performance reliability with gentle product processing

- Can be extended with measuring, control and regulation systems, circulation heating or cooling, reaction tanks, heat exchangers, vacuum and compressed air units

- Processing of toxic or oxygen-sensitive substances is possible

- Highest demands on production safety are met

- Convenient and variable operation thanks to manual control and computer-aided automation with video monitoring and process visualization

- Production of the entire plant from a single source

- Only high-quality materials such as austenitic stainless steel (1.4307, 1.4571, ...), fully austenitic stainless steel (1.4539, 1.4828, ...), duplex (1.4462, 1.4410, …), NiCrFeMo alloys with Ni > 40% (Inconel, Hastelloy, ...) are used

Technical details:

Depending on your need for integrated processes, we construct a wide variety of Terra® suction filters.

| Sizes | EFR 30 to EFR 180 |

| Filter area | 0.06 m² to 2.5 m² |

| Effective volume | 30 l to 2,300 l |

| Solids volume | 16 l to 1,000 l |