Filtration technology

Merkur® pressure strainers, press filter, pressure nutsches

Single-layer filters with diverse application possibilities

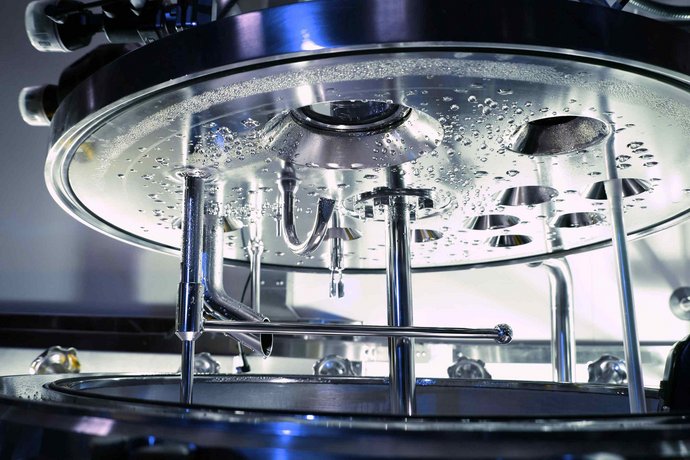

Various filter elements such as a filter layer, a filter cloth or a metal composite fabric can be inserted in the filling chamber of the Merkur® pressure vessel. Solids can thus be separated and washed or filter residues reprocessed from suspensions after precipitation or crystallization processes.

KASAG builds three types of pressure strainers for different applications:

- Merkur EF, a pure laboratory filter

- Merkur EFA, a pressure strainer with a large filling chamber for solids separation in batch operation

- Merkur EFD, a pressure strainer with a small filling chamber for the clarification and fine filtration of large quantities of liquids.

Advantages:

- Long service life and optimum safety for your product quality and your personnel

- Different process steps such as extraction, filtration, washing, dissolving and colouring can be combined in the same device

- Saves space and interfaces, thus generating a high return on investment

- Additional equipment with fittings, valves, agitators, chassis, measuring probes, gassing and riser pipes, CIP/SIP equipment and control systems possible

- Constructions and designs comply with GMP guidelines and FDA regulations

- Only high-quality materials such as austenitic stainless steel (1.4307, 1.4571, ...), fully austenitic stainless steel (1.4539, 1.4828, ...), duplex (1.4462, 1.4410, …), NiCrFeMo alloys with Ni > 40% (Inconel, Hastelloy, ...) are used

Technical details:

| Size / type | Filter area | Effective volume |

| EF 6 – EF 22 (laboratory filter) | 20 cm2 – 305 cm2 | 0.3 l – 11 l |

| EFD 30 – EFD 200 | 0.06 m2 – 3.0 m2 | 6 l – 560 l |

| EFA 30 – EFA 200 | 0.06 m2 – 3.0 m2 | 30 l – 3200 |