Process containers and storage tanks

for the chemical and food industry

The task of storing liquids hazardous to water or to their processing must be handled responsibly. In the building of the corresponding process containers, storage tanks, stainless steel containers, different factors must be taken into consideration. They are designed according to regulations, such as PED (AD-2000, SVTI, EN13445) or according to special standards, such as the Basel chemical standard BN76 and manufactured in stainless steel. Process containers and storage tanks have half-pipe coils, jackets or laser-welded structures (pillow plates) for heating and cooling purposes. KASAG is the competent place if you are looking for replacement, modification, extension or reconstruction of complete tank plants. We will share your responsibilities.

Receiving tank, 2,300 litre with half-pipe coils following PED in material 1.4307

4,000 litre stainless steel vessels following AD-2000 in material 1.4307

4,000 litre stainless steel vessels following AD-2000 in material 1.4307

63 m3 storage vessels following AD-2000, BN76 and with proven seismic load in material1.4404

40 m3 stainless steel tank following the Basel chemical standards, completely stained in material 1.4404

520 litre pressure tank following China Stamp, fully polished in material 1.4404

520

litre pressure tank following China Stamp, fully polished in material

1.4404

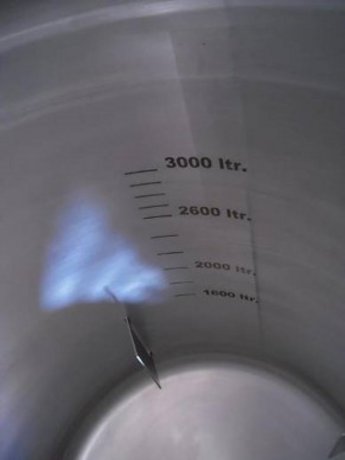

8,000 litre process tank with cone following AD-2000, fully polished in material 1.4404

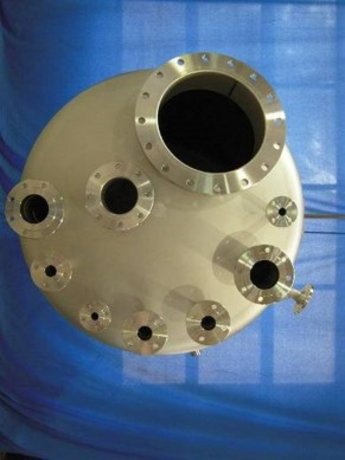

Autoclave, 10,000 litres following ASME U-Stamp Devision VIII in material 304L, 316L

Melt accumulator, 42 litres with lid and motor and jacket in material 1.4404

Melt accumulator, 42 litres with lid and motor and jacket in material 1.4404

Buffer tank with rotor mixer and scraper following PED in material 1.4307

Buffer tank with rotor mixer and scraper following PED in material 1.4307

50m3 storage tank, electrically heated, insulated in material 1.4307